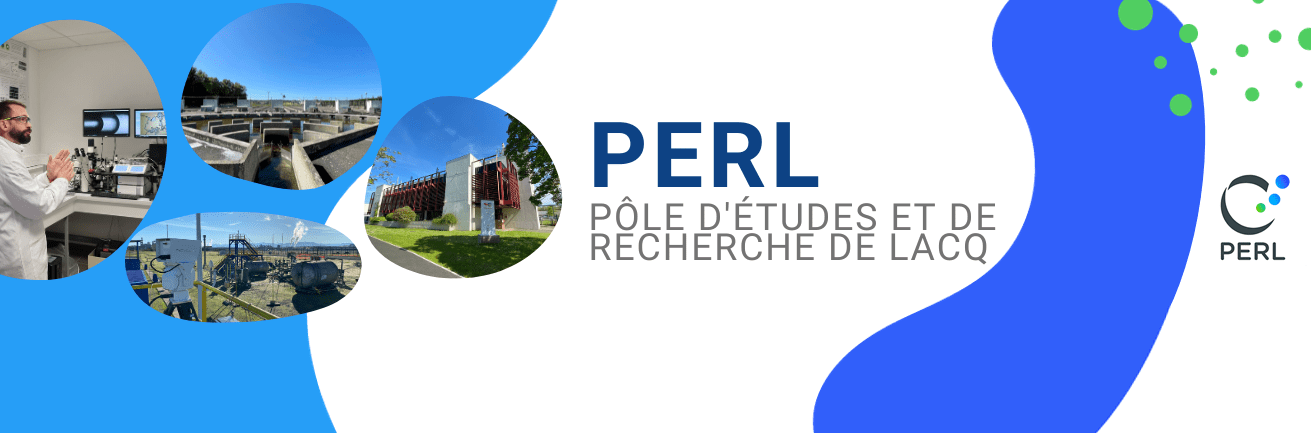

Created in 1959 to support the development of the Lacq basin, the Platform for Experimental Research in Lacq (PERL) plays a crucial role in Research & Development (R&D) at TotalEnergies, and is internationally acclaimed for its scientific and technical expertise.

The PERL is a Research & Development platform staffed by 120 employees working on three complementary sites: the laboratories (including PIC, the laboratory shared with the ESPCI), the Pilot Rivers and the Lacq Pilot Platform (PPL). The sites are used to run experiments from the laboratory to semi-industrial pilots. The three hubs of expertise at the PERL – Environment & Sustainable Development, Gas Separation & Treatment, Physical-Chemistry & Analyses – work together to reduce the impact of TotalEnergies’ activities on the environment and the climate, while fostering the development of new forms of energy. Semi-industrial pilots are set up and run at Pilot Rivers and the PPL. The research conducted at the PERL generates innovative solutions in phase with TotalEnergies’ ambitious objectives.